December Update

about 2 years ago

– Thu, Dec 21, 2023 at 06:22:22 AM

Hey gang.

Just making a quick placeholder update today.

What has been going on?

I know it has been 2 months without an update. I also know that I said that everything should be up and ready to go once the restaurant closed for the season, since the Kobold Press Wastes of Chaos minis were all molded and ready for production.

The reality of that is that I have struggled with the casting machine for more than half of that, with it being fully non-operational for 3.5 weeks of that time and only partially functioning until 3 weeks ago.

Immediately after I got the parts to repair it and got it back up and running, the Effincoolminis.com website crashed with a catastrophic failure. The website is absolutely crucial to the delivery of the Wastes of Chaos Kickstarter and due to the nature of its failure I was unable to access email accounts as well as any of the shipping orders for that project.

What this means is that instead of being able to work on this project at the level that I wanted to, I have been an equipment repair person and a website builder. I have also spent a good portion of everyday for the last 3 weeks packing and shipping miniatures, since a lot of Effincool Miniatures is down to essentially a one man operation.

Where I am at today:

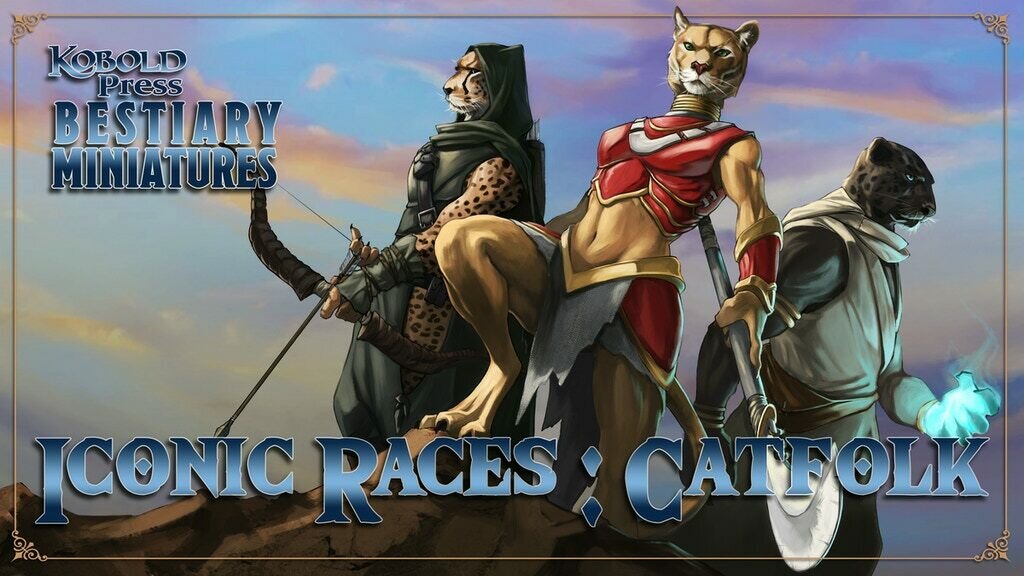

As of today I have all of the Catfolk molded for plastic and metal. I also have all of the miniatures for the first group of add-ons molded for plastic but not all of them for metal yet.

Since I now have enough of a backstock of cast miniatures for future backer orders for Wastes of Chaos, casting time on the injection machine has opened up. I will be able to begin casting and hopefully shipping orders by the end of next week. For now, this will only be the people who just have the Full Clowder and miniatures from the Add-Ons section. As I am able to mold more pieces, I will be able to ship the appropriate orders. This means that if you backed for everything it is still going to be a bit of a wait.

Next week.

I am planning on an update with pictures next week to show those models actually in the process of production. If you have specific parts of the operation you want to see, please comment and I will include those in the update!!

Finally,

I know it has been a ludicrous amount of time and I am ashamed that this has unfolded the way that it has, but if I could have planned for it, I would have...

Once again, sorry for the delay on updates and on delivery/production.

Thanks for your continued patience with me. :-(

John

Off to the running start!

over 2 years ago

– Mon, Oct 16, 2023 at 03:02:53 PM

Sorry once again for a late update. Ill keep it short and sweet.

Due to the lack of time for the past 4 months I still have not started full production of these miniatures. I have been working 7 days a week for 10-14 hours per day at my seasonal restaurant. This year was even more challenging than any previous and I wont bore you with the details.

What I can say with a sigh of relief is that last night was our official final night for the season at the restaurant. I have no other roadblocks in my way and will be able to dive headlong into finally putting the rest of these miniatures at the front of the line of stuff to do and getting them in your hands!

I know it has been a long road so far and we are still not done with the trip, but I anticipate being able to start shipping some of the orders that do not include Stretch Goal miniatures next week. With more miniatures molded and being produced every day.

For those of you who are losing faith, I understand. i would be in the same boat, but I can only keep giving you my word taht this project will deliver 100%. Thank you for hanging in there though and being as understanding as you have been.

Not much else to say except my next update will hopefully show off more production miniatures as well as trying to get a list of the pieces that are ready to ship and a timeline on when the rest will be available.

As always, thank you for your continued patience on this. It been a bumpy one!

John

August 10th update

over 2 years ago

– Thu, Aug 10, 2023 at 07:46:12 AM

I have some good news for once. The materials needed to mold and cast the plastic side of this project have finally arrived!

Buckets of plastic and mold materials showed up at the shop yesterday!

I also believe that I now have sculpts of every single miniature completed. I have also continued to work on finalizing these sculpts and prepping them for molding but that progress has been very slow.

Here are the renders of the last few pieces that were needed. I hope they inspire your excitement to see this project finally looking at a finish line. That line is still in the distance but getting closer each day.

Thanks again for your coninued patience with the tardiness of this project.

See ya all at the next update!

John

July Update

over 2 years ago

– Thu, Jul 27, 2023 at 06:04:50 AM

I am making just a quick update today to let you know that I am still cranking along at the pace that I am able to. I should have a much better and more detailed update next week.

I can say that I have all but two of the sculpts in my hands at this point and most of them are ready to be printed and molded. In my update next week I will take the time to render all of them and hopefully at that point the Dissimortuum and the Fey Revenant will be completed!

My time situation has not gotten any better over the last 2 months due primarily to the schedule at my restaurant and constantly being short handed there, but that season is rapidly coming to a close. I have one more month of really long hours there and September is a much more relaxed work schedule.

I will once again re-affirm that everyone will get their miniatures. To help ensure this from a financial end, I decided a few weeks ago to sell off my collection of classic arcade games. The money from that sale ensures that there will be no financial burdens on the delivery of this project, so I am still at the same issue that has plagued me for months....NOT ENOUGH TIME!

So until next week

June Update

over 2 years ago

– Thu, Jun 22, 2023 at 06:53:09 AM

Hey gang.

WHY DO YOU STILL NOT HAVE YOUR MINIATURES-First of all I have to start by saying once again, sorry for the delay on this update. This has been a tough 6 weeks. Those of you who know me personally know that I also own a seasonal restaurant and the opening of the restaurant this year took a lot of effort. Having said that I have still been chugging along on this project as much as I can every day.

I have been really tied up with getting the Wastes of Chaos miniatures ready to ship for Kobold Press, so that has taken a lot of time. Unfortunately my contract work for Tome of Beasts 3 and Wastes of Chaos miniatures are under a very strict contractual deadline so I have had to prioritize the work for those ahead of this project. I know that that sucks and I feel terrible that it is one of the main causes of the delays on this project.

It still just keeps boiling down to the same problem. I took on a lot of work with the expectation that there would be more people working on it than just me.

WHERE THE PROJECT SITS-There are 7 outstanding sculpts that need to be finished. The good news is that those are in the hands of some very talented people. The bad news is that none of them are currently completed enough to show you in an update. I have been promised that they will all be done by the end of the month.

I am currently working on the cleanup of all of the other existing models and test printing them to ensure that they look proper and fit together properly before we mold them. This is also a job that takes a lot of time and there is only me to do that work.

I have also ordered all of the rubber and plastic that we will need to manufacture these miniatures so that I am sure to not run into supply chain issues taht might further delay. That material should be in my shop by early next week.

I am not sure what else to say today except once again, thank you for your continued patience and understanding on this project. I know that I am asking for a lot of it at this point and believe me when I saythat I am grateful for all of your support!

John